Project info

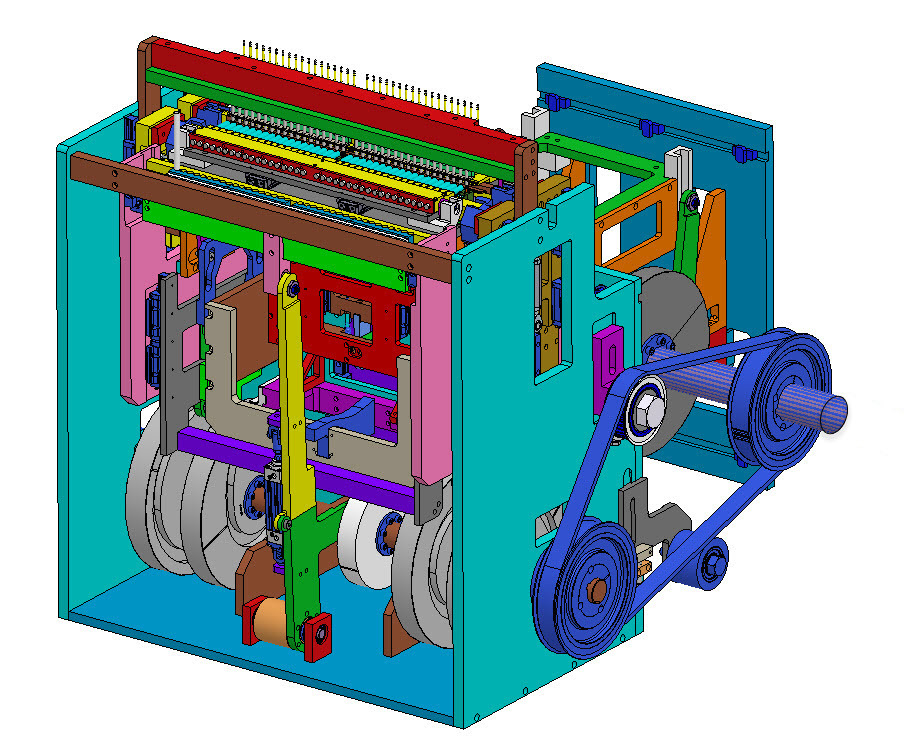

Multi-Axis Cam Machine Moves Tooling

The animation shows a cross-section of one product being assembled. Now multiply that by 36 assemblies deep and we have a complete manfold of caps being pressed onto syringe bodies in one cycle. The tooling moves between the load station and the press position (as shown below). All of the tooling must be supported by linear bearing systems and driven by cams.

How it works: All you need to know is that I used a software called MechDesigner to lay out all of the cams, linkages, and bearing slides. The mavel of this software is its ability to animate the motion and simultaneously see pressure angles and accelerations. Adjustments can be made on the fly to reduce undesireable forces, thereby making the motion smooth and the wear points nearly none existent.